Online customer service

WhatsApp

Service team:

在线客服

Mobile QR code

Webpage Copyright © www.rctowercrane.com

ICP0012458 Powered by Run Tower Crane 鲁ICP备16035304号-2 py:300.cn

Description

Components

RCT6015-10 Topkit Tower Crane Quick Details

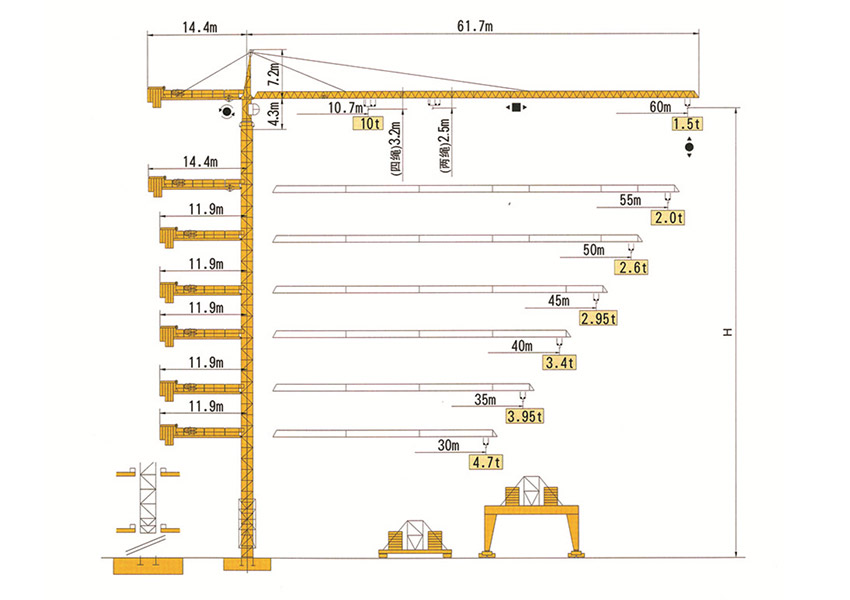

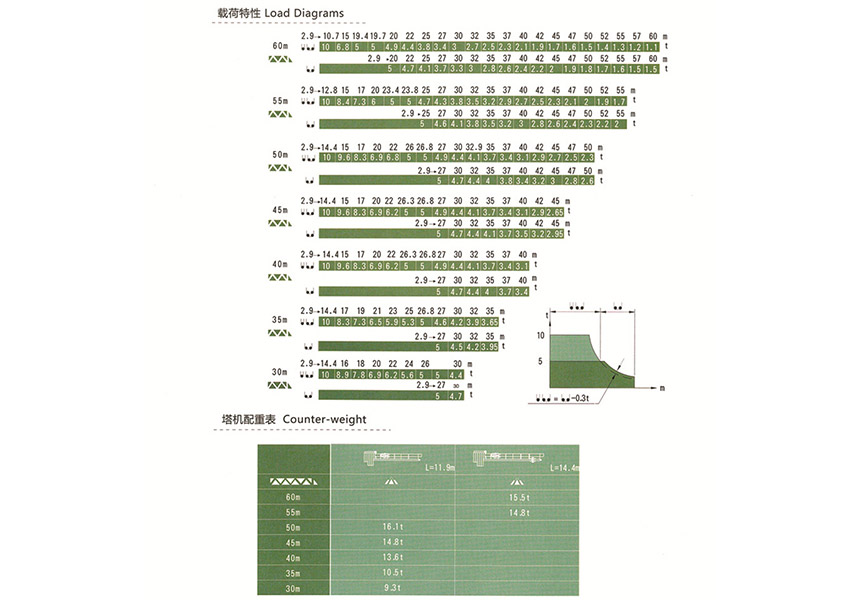

- Jib length:60m

- Max. load:10t

- Tip load:1.5t

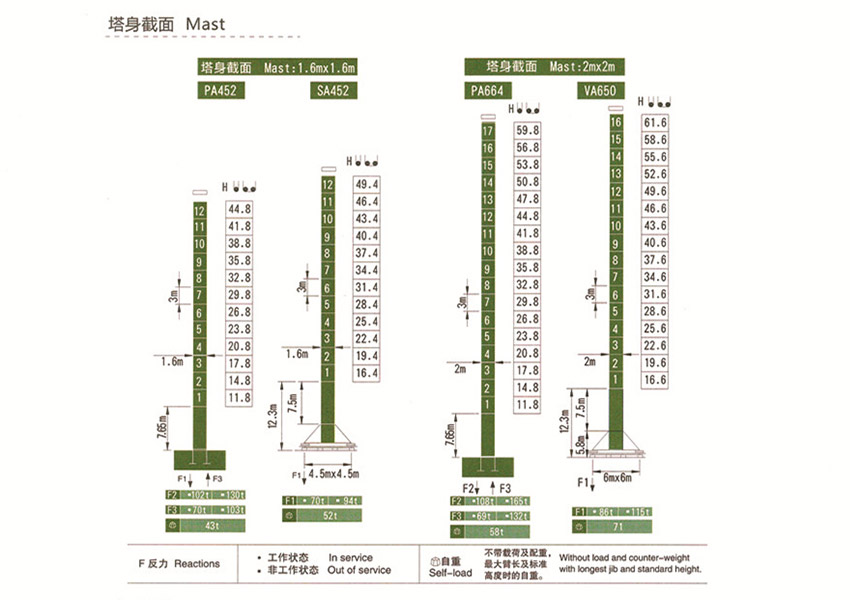

- Freestanding height:44.8m

RCT6015-10 topkit tower crane is developed with advanced technology by Run Tower Crane. As a high-level slewing and self-elevating crane, it has a compacting and novelty structure. Its performance has reached to international level. Its hoisting mechanism, trolleying mechanism and slewing mechanism are produced using Potain technology, which ensures excellent performance and reliable operation.

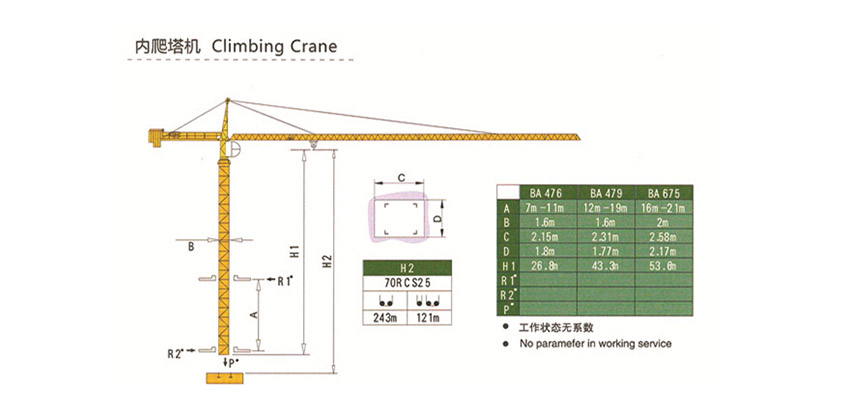

- By changing or adding components and auxiliary devices, the tower crane can be altered to walking, fixed attached or internal climbing type. Specifically, it can be fixed with ballasts or support bars to accommodate different construction situations. The maximum jib is 60m. The maximum hoisting capacity is 10t and the maximum attached height is 194.7m.

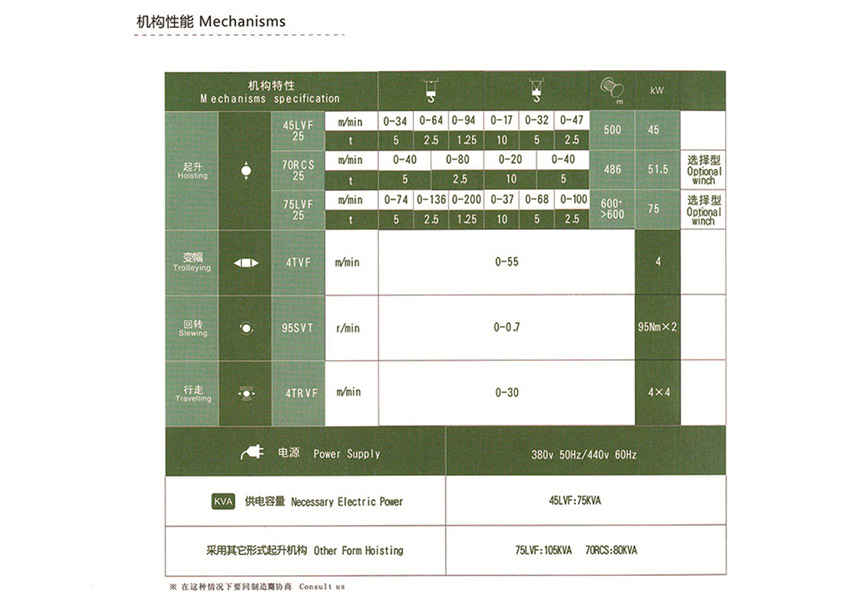

- Controlled by frequency converters, the hoisting mechanism is characterized by high working efficiency, long lifetime, low maintenance rate and comfortable manipulation. A hydraulic jacking system is adopted to lift the tower by adding mask sections.

- For safety and reliability of operation, the construction tower crane is also designed with various safety devices including load moment limiter, overload limiter, slewing limiter, trolley travel limiter and height limiter.

- Electrical control system of our fast-erecting crane features reasonable design and reliable performance. Major electrical apparatus elements such as contactors and intermediate relays are purchased from Schneider, which is a world famous company.

- As for assembly of the hammerhead tower crane, quick couplers are applied when installing the jib, the balance arm, the slewing mechanism and the tower body to ensure high efficiency, convenience and accurate positioning. As a result, labor intensity and risks are reduced significantly and hoisting time of a truck crane is saved greatly. Plate type mast sections are assembled using fishplates and pins, which leads to good interchangeability, easy warehousing and transportation and less cost.

Previous article

RCT6014-8 Run Tower Crane

RCT6024-10

Next article

Ddvisory